Artisan Revere Invests 30X More For Elmax® Steel

Because Better Steel Means We Can Make Better Knives

7 MINUTE READ

BY: DAVID OLKOVETSKY

There’s a dirty little secret within the kitchen knife world: most kitchen knives are made with low-quality steels that compromise on too many factors. If you have experience in the kitchen, you’ve certainly experienced what we’re talking about. Until now, there have been just two basic categories of kitchen knives: 1- thin/brittle and 2- thick/bad-geometry blades. Yes, there’s a plethora of variations, but you can sum up your options with just those two. Perhaps you’ve worked with an ultra-thin Japanese chef’s knife that slices easily. Great! The problem is, it chips on contact with nearly anything, including harder foods. If not, you’ve certainly experienced a heavy-duty German-style knife that cuts slightly better than a butter knife. Trust us, you may think it cuts well—it doesn’t. We founded this company to revolutionize the world of knives and create a third category: virtually indestructible, heavy-duty USA-made knives that cut better than custom-made Japanese blades. If you depend on your tools, then our knives are for you.

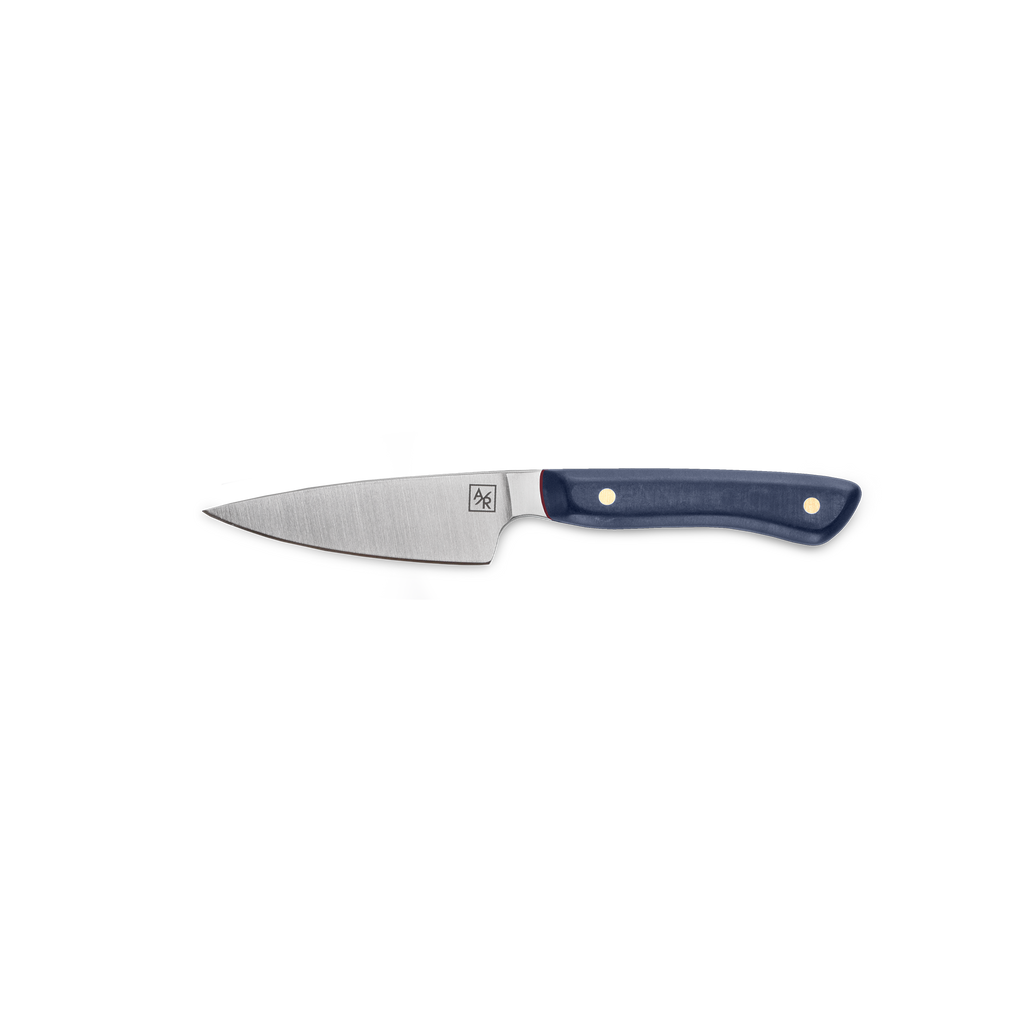

There’s a reason the Artisan Revere knife was deemed “the perfect chef’s knife” by the folks over at The Gadgeteer and was the only knife on Gear Patrol’s “The Most Important Kitchen Gear Releases of 2019”. Not only is it crafted with comfort and ergonomics at top of mind; it’s also created with high vanadium Elmax® super steel, a Swedish-Austrian 3rd generation powder steel. Simply put: Elmax is ultra-durable, strong enough to be ground to an incredibly thin and sharp edge, and normally reserved for the extreme conditions typically faced by outdoorsmen and U.S. Special Forces Soldiers. In fact, the U.S. Navy SEALs standard issue knife is made from Elmax!

Elmax also happens to be a steel that no other consumer-facing kitchen knife brand is using. Why? Well, it’s almost 30 times more expensive than nearly all knife steels, and since most of our competitors have been obfuscating (at best) or intentionally misrepresenting the quality of steel in their blades for decades, they’ve been able to get away with selling knives made with cheaper, lower-quality steel. Louis Brandeis, the famed Supreme Court justice, was quoted as saying, “sunlight is said to be the best of disinfectants”. We’re here to shine a disinfecting light on this practice, so that you can make an informed decision.

David Olkovetsky, the founder of Artisan Revere, grew up around knives, hand tools and metals, as the son of a jeweler. He spent 10 years as a steel analyst, investor, and armchair metallurgist. So when he started Artisan Revere, he knew he had to start with the best steel he could get his hands on. Even if that meant investing 30 times more on knife steel than the average knife company. Artisan Revere makes knives that:

-

Stay sharp 2.31x longer than other premium knives

-

Are 60% tougher and harder to chip

-

Require 40% less effort to cut most foods

-

Are highly corrosion-resistant

-

Have superb balance

-

Feature superior ergonomics (247 revisions for our chef knife)

-

Are crafted with sustainable, FSC-certified materials

No more hacking through tough squash and sweet potatoes, or sawing awkwardly, back and forth, through a beautiful cut of meat. Thanks to steel fit for extreme use, Artisan Revere’s incredibly thin knife cuts better, stays sharp much longer, and is harder to chip than most knives on the market.

Here’s a bit of technical, yet approachable background information about Elmax.

Elmax® Steel

Elmax is a 3rd generation Swedish-Austrian powder steel produced by Bohler-Uddeholm. The steel technology is 20-40 years more advanced than the powder steels of Japan. David Olkovetsky, Artisan Revere's founder, states:

-

Think about it this way, would you use a 20-year-old computer for work? Would you drive a 40-year-old sedan over a brand new one? Would you use a 20-year-old CD player over a brand new iPhone? Then why on earth would you use a knife made with antiquated technology?

Third-party Charpy lab testing shows that Elmax is a shocking 240% tougher than America’s best non-powder knife steel, 440C, and 60% tougher than one of America’s top powder knife steels, S35Vn. In other words: it’s a hell of a lot tougher than any other knife this thin. Elmax, heat-treated to 60-61 RC also keeps its edge 2.3 times longer than the “premium” German competition: Wusthof and Henckels. Simply put: your knife stays sharper for longer. Artisan Revere is able to grind our knives thinner (0.012” behind the edge for our chef knife) because the steel is so tough. Our friends over in Germany tend to grind their blades to .020”+. Basic physics formulas tell us that Artisan Revere knives cut with less force.

The Powder Metallurgy Process, Simplified

Here’s the quick-and-dirty on powder metallurgy (PM): The PM process allows our steel making partners to 1- infuse more alloying content, and 2- make a denser, more homogenous steel, that makes for high alloy tool steels with superior toughness and wear resistance. Translation: increased shock resistance and edge retention, for tools that last longer, perform better, and require less repair.

Compared to Japanese PM steels like HAP-40 and SG-2, our steel produces 738 times less emissions.

It’s important to understand that not all steels are created equal. Not even close. Our steel suppliers produce steel via the Electric Arc Furnace method, which consumes a stunning 9 times less energy than most knife steels made via the Blast Furnace method primarily deployed in China and Japan. Our steel is primarily produced in Sweden, where the electric grid is only 1% fossil fuels. Compared to Japanese PM steels like HAP-40 and SG-2, our steel produces 738 times less emissions! Once the steel ingot is created, it is then liquified. The molten steel is then poured through a blast of liquid nitrogen, instantly creating particle-sized steel ingots with a highly refined carbide structure. Nitrogen allows the metal to instantly solidify.

Note: more than 99% of the steel produced globally uses multi-ton ingots—not the particle-sized ingots we use. The smaller the ingots, the faster they cool. And with steel, faster cooling leads to smaller, more concentrated and homogenous carbides—and smaller, more concentrated carbides mean better consistency and higher toughness. This is why we can get our knives much thinner than normal, and still prevent chipping. Those particles are then pressed and re-heated in a metal canister via a process called Hot Isostatic Pressing, to make one solid ingot. The ingots are then forged and rolled to thickness. This processing effectively replaces the need to forge, i.e. hammer, the steel, a highly antiquated process that is useful primarily for low-carbide steels.

Alloy Content

It’s not simply the 3rd Generation Particle Metallurgy process that our partners at Bohler-Uddeholm employ that makes our steel special. The chemical composition makes an enormous difference as well. For instance, carbon increases steel performance by making it harder and stronger—and at 1.7% carbon, Elmax has 3x more than Germany’s most popular knife steel (X50CrMoV15), and 60% more than Japan’s most popular knife steel (VG-10). Elmax steel's alloy content also contains 3% vanadium—15x more than German and Japanese steels. Vanadium is the the "super" in super steel. Vanadium forms extremely hard carbides, which dramatically increase how long steel stays sharp. In other words, vanadium increases wear resistance. We’re able to push so much carbon and vanadium into our steel because of Bohler-Uddeholm's 3rd generation powder process. The result? Durable, highly chip-resistant steel that will stay sharper, much longer and cut far better.

Elmax’s Alloy Composition Stacked Up Against The Competition:

3rd Generation Powder Metallurgy: A Visual Guide

Most knife brands out there haven’t figured out how to master toughness (Charpy testing), edge retention (CATRA TCC testing), and cutting ability (we’ll use thinness behind the edge as a proxy). At best, they get 1 out of 3. Think about those ultra-thin Japanese kitchen knives that cut like magic but get chipped and damaged too easily.

Or those “premium” German blades that stay tough, but cut only slightly better than a plastic knife. This is where Elmax shines. The below charts represent the tradeoffs made between important variables, like toughness, edge retention, and cutting ability, in the form of ingot steels, 1st generation powder steels, 2nd generation powder steels, and 3rd generation powder steels (like Elmax).

Thinner knives cut much better but need to be babied.

Enter Elmax. Thinner knives that are harder to chip.

"Cutting ability" is the energy required for cutting, whereas "sharpness" is the energy required to initiate a cut. Knives that are thinner, with more acute edge geometry, ex. 15 degrees, cut better than thicker knives with a more obtuse edge, ex. 22 degrees.

3rd generation steels outperform all of the older technologies significantly because they are purer and have drastically smaller carbide sizes. Impurities in older processes cause major weaknesses in the microstructure of steels, as do large carbides. The 3rd gen process solves for these far better than Gen 1 and 2, and our partners at Bohler-Uddeholm are the world leaders.

The Best Steel, For The Best Knives. Period.

By investing in high vanadium Elmax, Artisan Revere’s done what no other knife company has: craft ultra-thin knives that cut superbly, stay sharp longer, and resist chipping and corrosion. With proper care, you’ll never have to worry about chipped blades or dull moments ever again. We’re confident we have the best knives on the market—and we’re sure you’ll agree.

Don’t just cook; cook with the best possible tools, made with the best possible technology, crafted by America’s top makers. That’s where you’ll find your edge. If you’re ready to stop hacking your food to smithereens, check out the Artisan Revere Chef’s Knife here.

Shop Our Top Tools

Customer Reviews

After a few weeks of using this knife it has quickly replaced all others as my go-to for all my prep work. This thing is sharp and feels great in the hand. My wife loves it because of how light it feels. This is a serious tool in the kitchen and I look forward to a lifetime of hard use.

My husband got me this knife for a Christmas gift. I cook all the time and I really wanted a good knife. This is definitely that!!! I cannot believe how easily it cuts through vegetables.. anything I am chopping up!! This is one Fantastic knife. We went back on your website to getting a chopping board now!!! 😆

This is the best knife I have used until now. It is extremely sharp and comfortable to use. What impressed me the most is how lightweight it is! I definitely recommend. This is one of those knives that can last a lifetime. One of these days I will save up money to get the other two.

As I've gotten older, I've begun to recognize the importance of eating handmade food from fresh ingredients. Not only is the food healthier, it tastes tremendously better.

However, a good knife is one of the areas I've neglected in my pursuit of crafting handmade food. For some reason, I've held the perception that a knife is a knife is a knife. I was wrong.

Before Christmas, I decided that I wanted to treat myself and invest in my last knife. To support my efforts in finding the right knife, I use the following prompt in ChatGPT:

== BEGIN PROMPT ==

You are a master chef who specializes in US independent knife makers.

I'm in the market for a new chef's knife. I am looking to spend less than $400. I want a knife that is known for flexibility, retaining its edge, and durability. Give me some of the best options from US independent knife makers.

Create a table with the top ten options with links to their sites.

== END PROMPT ==

Artisan Revere was one of the companies listed. After following up with other prompts to refine what I was looking for, everyday use retains its edge and ease of maintenance, it was clear that Artisan Revere was the best option for me.

Although I spent more than I initially planned, having used my Artisan Revere chef's knife for the past three months, I couldn't be happier with my investment and feel it was worth every penny.

Having such a good knife pushed me to invest in a better cutting board and has encouraged me to push my already fanatical passion for cooking even further, which has had a corresponding impact on my enjoyment of the entire cooking experience.

And while I could go on and on about the tremendous attributes of my knife, what I appreciated even more was David Olkovetsky, the CEO, calling me to understand my cooking style and confirm I had what I needed to take care of my knife. This level of hospitality, combined with a tremendous product, has made me a fan that will only ever use and gift Artisan Revere knives.

If you're on the fence about investing in a knife. You'll never regret investing in an Artisan Revere knife.

We bought 2 chef's knives for a couple of our customers as an end of project gift. It was awesome to find such high quality knives, they look and feel amazing. David the owner of Artisan Revere was very helpful and even helped us get the customers names engraved on the leather sheath and knife.

View Our Top Articles