HOW TO CHOOSE A CHEF'S KNIFE

What Makes A Great Knife for You?

10 MINUTE READ

BY: DAVID OLKOVETSKY

Let’s get a universal, undisputed truth out of the way: the chef’s knife is the one tool no chef or home cook can live without. When you have a sharp, durable, and comfortable chef’s knife in hand, you can prep almost anything in the kitchen—and do it all quickly, easily, and safely.

But knowing how to choose a chef’s knife is half the battle. And with all the marketing gimmicks out there, it’s hard to figure out where to start. So here’s our guide to choosing the best chef’s knife.

Contents

What Should I Look For In A Chef's Knife?

There are five main factors that make the best kitchen knives.

A knife that is extremely comfortable and won’t ever give you calluses,

A knife that cuts well due to good edge geometry,

A knife with a razor sharp edge,

A knife with an edge that stays sharper longer, and,

A knife that is harder to chip.

Let’s Talk Knife Handles, Comfort & Calluses

The knife handle is where your relationship with your knife starts, and this one piece of the knife is just as important as the business-end, i.e. the blade. Would you buy a car with a superb engine that was missing a windshield and had car seats that caused you pain? If not, you shouldn’t put up with a handle that is rough. This is why comfort is of paramount importance especially for advanced home cooks and professional cooks. Even the great Anthony Bourdain dedicated a bit of Kitchen Confidential to the callus.

At the base of my right forefinger is an inch-and-a-half diagonal callus, yellowish-brown in color, where the heels of all the knives I've ever owned have rested, the skin softened by constant immersion in water. It distinguishes me immediately as a cook, as someone who's been on the job a long time. —Anthony Bourdain.

Knife-making has evolved and improved, and soon, calluses will be a thing of the past. So, what makes a comfortable handle?

The handle of your knife should have no rough edges or corners, especially towards the front.

The tang should be fully flush and smooth with the scales. Scales are the handle pieces connected to the tang.

The spine should be smoothed over and not boxy. This is the only way to guarantee no calluses.

The bolster, or heel, of the blade should also be softened. This is also to avoid calluses.

If your knife handle is rough or causes you calluses, we suggest bringing it to a local knife-maker to smooth out the handle—it does not need to cause you pain. Alternatively, you can find a local woodworker or machinist who will be able to help you out.

To keep your knife handle in good condition from the start, wash and dry it immediately after use. Do not use rough brillo or other rough sponges. Never ever put any wooden material in your dishwasher. If your knife is made from wood or Richlite, add an occasional drop of food grade mineral oil so it retains its original tactile response. That’s it for handle care. For more information, check out our Ultimate Guide to Knife Care.

The Business End Of Your Knife

In the past few decades, there have been remarkable advances in steelmaking. I would know, I analyzed steel and steel companies for 10 years before I started Artisan Revere. All kitchen knives—not just chef’s knives—can be thinner, sharper, and, importantly, more comfortable. But since most cooks and professional chefs don’t know what to look for when it comes to steel, nearly all knife companies use cheaper, subpar materials in their knives. Let’s all come together and insist that knifemakers start using better steel, because the right equipment makes all the difference. You should pay attention to the following:

Knives Cut Well Based On Geometry

German metallurgist, Roman Landes, has written, “geometry cuts”. The best kitchen knives cut well because they are thin. Here are some knife geometry basics you should know about before you buy a knife.

The most important determinant of how well a knife cuts, aka, it’s “cutting ability” is how thin the knife is behind the edge. This is often referred to as “behind the edge thickness”. And yes, a more acute edge angle (15 degrees vs 20 degrees) has a larger impact on edge retention, perceived sharpness is more affected by thickness behind the edge. Also, the edge grind is very easy to adjust via a whetstone or electric sharpening. So for now, focus on getting a blade that is thinner. How do you do that? Pick up a cheap caliper for $15 and bring it to the store.

Heavier knives, usually made by German, French, and American companies and makers, tend to be very thick behind the edge. As a result, these thicker knives cut poorly. These knives are designed to avoid chipping at the expense of cutting ability and are typically made with cheap steel. You need to use more force to push or slice through foods. Think: Wusthof, Zwilling-Henckels, Sabatier, Laguiole, Cutco. All of these brands make thick, soft knives, with cheap, soft (54-58 Rockwell), low-to-mid carbon, low alloy steels.

They can claim they’re high alloy, or high-carbon, or that they have a proprietary grinding technique until they’re blue in the face—but it won’t change the fact that their knives dull quickly and cut poorly. A high carbon knife is 0.83% carbon or higher. Sorry to all those companies mentioned previously, your knives are NOT high carbon and they do not come sharp. More importantly, because the steels are thick behind the edge, these knives cut poorly, no matter what their marketing departments say. It’s simple geometry.

Thin knives, usually made by Japanese knife makers and a number of talented blade smiths, cut better. The problem with most thin knives, is that they chip easily, and are primarily designed for soft proteins and vegetables, not for harder foods. You’ll find yourself switching between your thin slicing knife and your thicker knives anytime you’ve got a harder item to process. For most working chefs, and nearly all home cooks, switching between knives is simply not an option. If you’re able to, bring a digital caliper with you when purchasing and ask to measure the thickness behind the edge. Anything less than 12 thousandths of an inch will be too brittle as an all-around knife. This measurement is performed right where the edge grind meets the primary bevel.

Alternatively, if you are purchasing a knife online, ask the maker how thin he or she gets behind the edge. Also, ask them if you can try the knife for a period. Any respectable maker will be confident in their blades and should allow this. FYI, at Artisan Revere, we have a 100 day guarantee. If you don’t love your knife, return it, and we’ll pay for return shipping and donate the blade.

How do you know if your knife cuts well? There are a few simple tests you should perform on your knives before you commit to them. 1. Do they easily slice through a tomato, and 2. Will the knife easily slice through a piece of magazine paper without getting stuck. These first two tests tell you if the knife is sharp. It’s also important to find out if the knife cuts well. Cutting ability (how well a blade moves through food) is very different from sharpness (how well a knife initiates a cut).

This may sound a bit out there, but if you're going to spend hundreds of dollars on a tool, you should be able to try it before you commit forever. That's why we recommend you test for cutting ability. This is our #3. Take a sweet potato and a few onions with you to the store. If you can cut through the sweet potato without feeling like you’re cutting down a tree, and if the knife flies through the onion, that knife cuts well. These simple tests will tell you if your knives are sharp and have good cutting ability.

The Best Kitchen Knives Come Razor Sharp

Let’s be clear: if your knife comes anything less than screaming sharp, the folks who made it aren’t that good at their jobs. The role of the knife is to make cutting as easy as possible, so if your knife doesn’t shave arm hair or at a minimum, easily slice magazine paper, it is not sharp, and likely not well-made. There are several important factors when assessing cutting-ability and sharpness, and for simplicity we include them all here. As a reminder, cutting-ability can be defined as how well a blade moves through food, while sharpness is how well a knife initiates a cut. In the following list, numbers 1-4, affect both cutting ability and sharpness, while 5 and 6 are exclusively related to cutting ability.

Edge width or radius, which is another way of saying did you achieve an apex when sharpening? A good knife maker can get a radius well below 1 micron.

Edge grind angle (15 degrees per side vs 20 degrees vs 25 degrees, etc.)

Thickness behind the edge, measured where the edge grind and primary grind meet.

Secondary grind (often referred to as secondary bevel, or edge grind)

Primary grind (from the spine down to the secondary grind).

Type of primary grind: hollow, flat, convex, which primarily affects how well the knife moves through different materials and how much it sticks.

These six properties of geometry affect how a blade cuts. A full post will be dedicated to geometry, but for purposes of this article, here’s what you need to know. More acute angles lead to better cutting-ability. 15 degrees ground 50/50 will cut better than 20 degrees ground 50/50, all else equal. All else, however, is not always equal. Narrower behind the edge thickness leads to better cutting-ability. Note: knives that are too thin, many Japanese blades fall into this category, tend to have poor edge stability. These knives often experience major edge chipping. It is only through the use of super steels like Elmax that you can ever get truly thin while retaining robust toughness and edge stability.

At Artisan Revere, we don’t think you should have to sacrifice cutting-ability and cutting performance for toughness and chip resistance. Kitchen knives can, and should, have it all, and that’s why we invest 30x more in our knife steel than other knife makers. This is why we invest in Elmax® steel, which, after quite a bit of experimentation, is the steel we believe is the best all-around knife steel for most hard-use knives. Elmax steel, along with other powder super steels like M390, S30V, S35VN, S45VN, CTS XHP, MagnaCut, SG-2/R2, and HAP-40 are ideal for grinding thin, hard knives that stay sharper and cut better, longer.

A Razor-Sharp Edge That Stays Sharp & Has Superior Cutting-Ability

Sure, this one might seem obvious. Your kitchen knife should stay sharper for longer. Unless you’re one of the rare breed of folks who love sharpening their knives often, you likely prefer to focus on cooking, and enjoying the fruits of your labor—delicious meals, hopefully enjoyed with family and friends. But, if your knives go dull quickly or chip easily, then you’ll find yourself either sharpening them all the time, or getting frustrated and cooking less.

If the steel used in the blade is softer and more prone to dulling like most Western blades, or is very hard and brittle, like most Japanese blades, it will be more likely to experience macro-chipping. This is why edge retention, i.e. how long a knife stays sharp, is a combination of wear resistance (how long it takes the metal abrade) and toughness (how hard it is to chip from direct impact, lateral loads, or twisting). The last thing you want to worry about when you’re prepping a meal for your loved ones is a dull or chipped knife. (A sharp knife is, ironically, safer to use than a dull one.)

So, how can you know if a blade will stay sharper longer? David Olkovetsky, the owner of Artisan Revere and a 10-year steel research veteran, recommends looking for more advanced, high-quality powder steels, which will give you both an ultra-sharp cutting edge and a strong and tough blade that can withstand the pressures of a busy kitchen.

Here are some high-performance powder steels which will stay sharper, longer:

Elmax (Sweden) ― 3% vanadium (more on this in second)

M390 (Austria) ― 4% vanadium

-

SG-2 (Japan) ― 2% vanadium

...as well as the following American powder steels:

MagnaCut — 4% vanadium

CPM154 ― 0-0.4% vanadium

CPM S35VN ― 3% vanadium

CTS-XHP ― 0.45% vanadium

A chef’s knife using any of these powder steels, as long as it’s designed and heat-treated correctly, and ground thin, should be able to handle almost any ingredient in your kitchen. It should be able to chop carrots, dice butternut squash, thinly slice a ripe tomato, and break down poultry—over and over again, and with minimal pressure. If you have questions about a particular knife or brand, you can always reach out to us directly.

About That Vanadium…

You probably noticed the vanadium percentages we listed next to each powder steel. This virtually indestructible element allows knife blades to hold their sharp edges, putting the “super” in “super steel.” The catch: much more than 3% vanadium, and your knife will become extremely difficult to sharpen—a major issue, considering the fact that all knives, no matter the steel quality, will eventually need to be sharpened to maintain peak performance.

Look for powder steels like Elmax (3% vanadium), for top-of-the-line knives that are both ultra-tough and easy to sharpen and maintain. Just remember, check for cutting ability by confirming that it easily moves through a sweet potato and onion. For some independent research about Artisan Revere knives, made with Elmax, see these articles from Cooking Light and The Gadgeteer. Here’s where you can pick up your very own Artisan Revere Chef’s Knife.

Knives Shouldn't Chip Out Easily

A great knife should stay sharp for a long time, and a part of staying sharp means not chipping. Sorry to Shun, MAC, Kikuichi, and the other Japanese brands still using AUS-10, VG-10 and their look-alikes, these steels chip out for all but the gentlest knife users. Edge retention is based on two factors: the wear resistance of the steel, and how well it resists chipping, twisting and other distortions. We’ll keep this section simple, since we already wrote about Powder Metallurgy here, and you can also get deeper into the weeds with Dr. Larrin Thomas’ excellent article on Powder Metallurgy.

What makes a knife tough? Knives that have more refined, homogenous carbides, as accomplished via the powder metallurgy process, are generally tougher than knives with similar alloy percentages, produced via traditional steelmaking. Knives that are thick behind the edge and have wide edge angles are tougher than thin and acute knives. Knives that are lower Rockwell are generally tougher than high Rockwell knives. Knives that are low alloy are generally tougher than knives that are high alloy.

High toughness knives also generally dull quickly. Within the profession, we often refer to tough knives as beaters—since you won’t mind beating them up. So let’s keep this one simple. If you want performance and toughness, buy knives made from powder steels like Elmax that are ground thin and hard, because they can still maintain superb toughness thanks to the powder metallurgy process.

In A Nutshell...

Your chef’s knife should be your most reliable sidekick in the kitchen. Take some time to do your research, and invest in a knife that stays sharp longer, cuts better, is tougher to chip, and feels great in your hand. Choose a knife made with a high-quality powder steel containing about 3% vanadium, for a knife that will last you a lifetime.

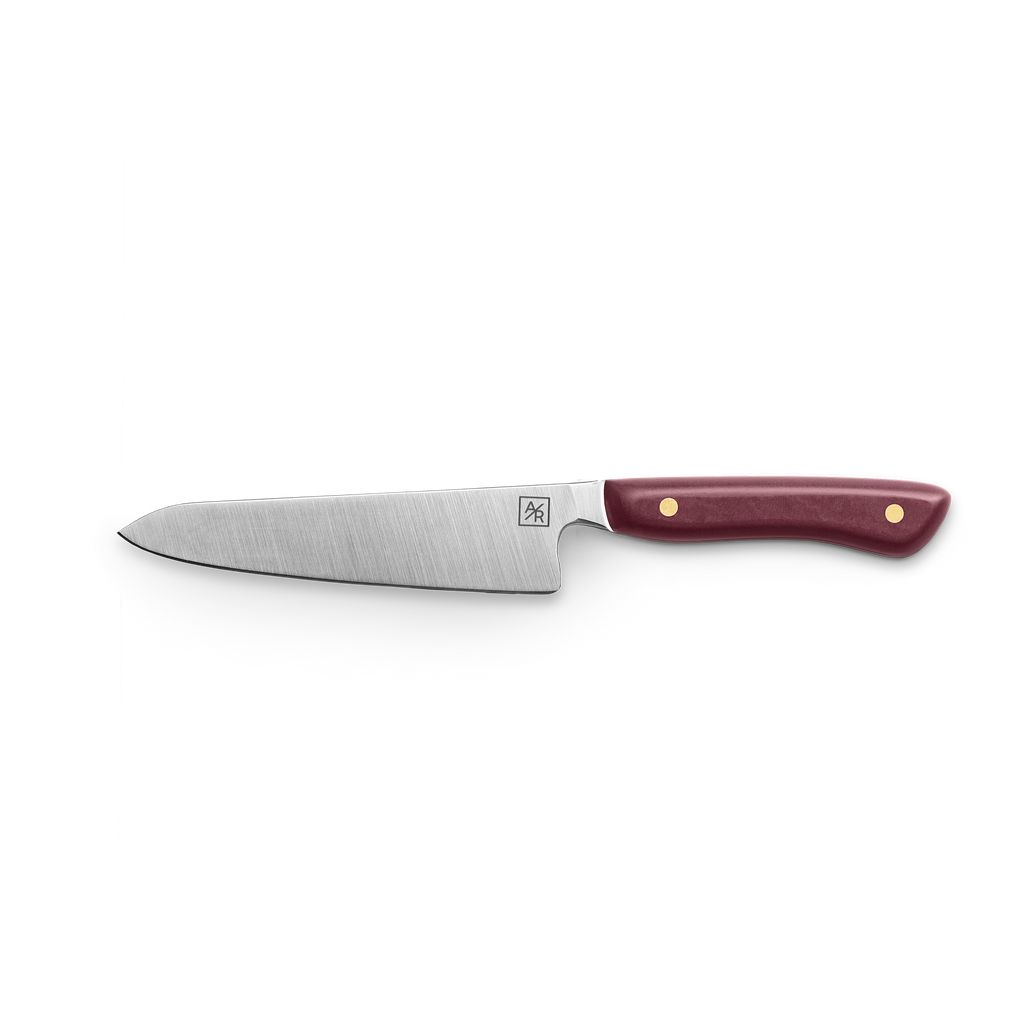

Don’t know where to start? Go for the Artisan Revere Chef’s Knife, made with Elmax High Vanadium Super Steel—and tested by hundreds of home cooks and professional chefs. We promise it’ll soon become your workhorse in the kitchen; you’ll wonder how you ever lived without it.

Shop Our Top Tools

Customer Reviews

After a few weeks of using this knife it has quickly replaced all others as my go-to for all my prep work. This thing is sharp and feels great in the hand. My wife loves it because of how light it feels. This is a serious tool in the kitchen and I look forward to a lifetime of hard use.

My husband got me this knife for a Christmas gift. I cook all the time and I really wanted a good knife. This is definitely that!!! I cannot believe how easily it cuts through vegetables.. anything I am chopping up!! This is one Fantastic knife. We went back on your website to getting a chopping board now!!! 😆

This is the best knife I have used until now. It is extremely sharp and comfortable to use. What impressed me the most is how lightweight it is! I definitely recommend. This is one of those knives that can last a lifetime. One of these days I will save up money to get the other two.

As I've gotten older, I've begun to recognize the importance of eating handmade food from fresh ingredients. Not only is the food healthier, it tastes tremendously better.

However, a good knife is one of the areas I've neglected in my pursuit of crafting handmade food. For some reason, I've held the perception that a knife is a knife is a knife. I was wrong.

Before Christmas, I decided that I wanted to treat myself and invest in my last knife. To support my efforts in finding the right knife, I use the following prompt in ChatGPT:

== BEGIN PROMPT ==

You are a master chef who specializes in US independent knife makers.

I'm in the market for a new chef's knife. I am looking to spend less than $400. I want a knife that is known for flexibility, retaining its edge, and durability. Give me some of the best options from US independent knife makers.

Create a table with the top ten options with links to their sites.

== END PROMPT ==

Artisan Revere was one of the companies listed. After following up with other prompts to refine what I was looking for, everyday use retains its edge and ease of maintenance, it was clear that Artisan Revere was the best option for me.

Although I spent more than I initially planned, having used my Artisan Revere chef's knife for the past three months, I couldn't be happier with my investment and feel it was worth every penny.

Having such a good knife pushed me to invest in a better cutting board and has encouraged me to push my already fanatical passion for cooking even further, which has had a corresponding impact on my enjoyment of the entire cooking experience.

And while I could go on and on about the tremendous attributes of my knife, what I appreciated even more was David Olkovetsky, the CEO, calling me to understand my cooking style and confirm I had what I needed to take care of my knife. This level of hospitality, combined with a tremendous product, has made me a fan that will only ever use and gift Artisan Revere knives.

If you're on the fence about investing in a knife. You'll never regret investing in an Artisan Revere knife.

We bought 2 chef's knives for a couple of our customers as an end of project gift. It was awesome to find such high quality knives, they look and feel amazing. David the owner of Artisan Revere was very helpful and even helped us get the customers names engraved on the leather sheath and knife.

View Our Top Articles